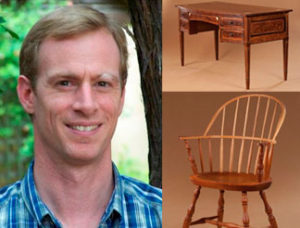

[This article is based on an interview with Frank Strazza, Ploughshare woodworking instructor.]

Ploughshare: Can you comment on how woodworking fits into an agrarian lifestyle and the restoration of a local cottage economy?

Frank Strazza: In many ways, it seems like we’ve gotten away from simple tasks—working with our hands and using simple hand tools that people have used for generations. It’s only been in the past 50 or 60 years that people have really turned their back on the traditional ways of doing things and rejected the use of traditional hand tools for simple tasks.

Let’s take a hand saw, for example. Until about 60 years ago, when people would frame houses, they would use hand saws to cut framing lumber. A sharp handsaw will cut through 2×4’s as fast as a circular saw.

Suppose you need to build a chicken coop—I built a chicken coop with my children, and instead of using a circular saw, we used a hand saw. Now I’m building a shed, and I’ve been using hand tools because the shed is far away from any source of electricity, and it would take more time and effort to drag an extension cord out there. It’s faster to do the work by hand, but to do that, you need to have the hand skills. You also need to know how to sharpen the tools because a dull hand saw will not work.

Many people no longer have the skills to sharpen saws. When they try to use a dull saw, they say, “This doesn’t work.” So they use a circular saw instead because you can buy a brand new, sharp blade at the store for $10-20 and get on with your work. But if you have the skills to sharpen a handsaw, then with five minutes of sharpening, you can cut through wood very effectively and very quickly. Hand tool woodworking fits into an agrarian way of life because you develop skills that you can use in many different projects on your homestead.

As far as fitting into a cottage economy, I think there are many ways someone can make a living by making projects in their home shop using hand tools (and power tools). Working out of the home or home shop is very doable. Having made furniture for a living for years as a sole source of income, I can say it’s a lot of work, so you definitely need to love what you’re doing.

Yes – it was not long ago that handsaws were used for most tasks on the jobsite. My first job in 1973 was as a carpenter’s helper doing mostly renovation work. In each of our tool boxes we had a crosscut saw, a rip saw, a coping saw and a keyhole saw. The crew had a miter box with a crosscut backsaw and a miter trimmer. In trimming out windows and doors, I would cut the trim slightly over with the miter box and then use the trimmer to shave the joint to a precise fit. The coping saw was obviously for coping joints for trim. In 76 I moved to Texas and got a job doing trim carpentry and framing. I still used my handsaws for installing hardwood trim, but by then nearly everyone was using a worm-drive Skillsaw for framing. As far as trim carpentry went, most crews in Central Texas would rough cut the trim and fill in the gaps with caulking compound. They would miter all trim joints – no one seemed to know how to cope a joint. Not long after that, everyone had an electric miter box.

Interestingly enough, people will force a dull circular saw or table saw blade through a board because brute force will get through it. Then they complain about the quality of the cut. It’s all about sharp regardless of the tool. However, there is nothing like the feel of a handsaw and the reasonable assurance that if you started the cut with ten fingers, you’ll end the cut with ten fingers. I think hand tool work heightens observation and attention to your surroundings – a beautiful place to be in complex world.